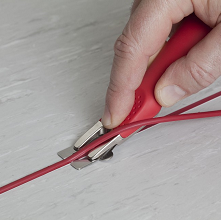

Mozart has invented a complete new cutting principle based on the idea that the blade slides flat over the floor, which means that the highest point of the floor surface determines the cutting depth. Consequently it’s pretty much impossible to damage the surface at all; guaranteeing a steady, excellent result.

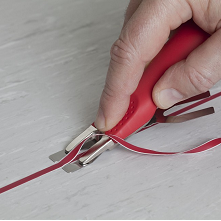

The Mozart weld trimming tool is designed to cut hot weld after welding. The design enables the user to cut off the excess weld, leaving a small amount for cooling purposes, after which the guide plate is twisted around revealing the cutting the blade. The tool is ergonomically designed to fit comfortably into the hand and has less exposed cutting edge (safety in mind) as the cutting edge is the same or similar size to the width of the weld rod.

When using, the operator presses down onto the finger plate until the blade touches the guides, after which you just push the tool forward over the weld.

Amongst the advantages are that the cutting edge lasts a lot longer particularly on safety flooring, you do not have to sharpen the edge as previous spatulas, you just change the blade.

The time saving just on sharpening, far outweighs the cost of the blades, more importantly it very easy to use, with really good results.

To give you the best possible experience, this site uses cookies. Continuing to use www.fi-techeurope.com means you agree to our use of cookies. If you'd like to learn more about the cookies we use please visit our

To give you the best possible experience, this site uses cookies. Continuing to use www.fi-techeurope.com means you agree to our use of cookies. If you'd like to learn more about the cookies we use please visit our