With a history spanning from the 1920’s, MOZART AG has developed into one of the world’s leading producers of technical blades, through excellence in quality – in fact to ISO 9001 quality certification.

Mozart products will always give you the best quality; for cutting and dividing, for perforating and breaking, for scraping and notching. Blades are specially made from materials best suited to the individual application – from tool steel to solid tungsten carbide – according to customer’s specifications. And Mozart’s special blade production know how ensures outstanding cutting performance and long service life.

Thanks to the high quality standards of production, Mozart now produces an extensive range of industry standard blades through to individual special products for customers from the most varied fields. Foils, paper, plastics and foods – it doesn’t matter what you want to do. Mozart has the right solution

for all industrial applications.

Blades for the Fibre & Plastics Industry

Preferred partner of industry

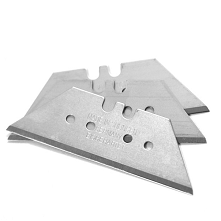

From Polypropylene or Cellulosic fibre tow to Glass and Carbon fibre to reprocessing Kevlar waste - Mozart blades are proven performers. Superior reliability and excellent stability under load results from the use of high quality, special alloyed strip steel and stringent process quality controls. Individual model series (suiting Lummus, DM&E and other fibre cutters) are precisely adapted to the special needs of our customers, by the use of optimised grinding angles and special coatings. Tight control of tolerances and polishing ensures the desired cutting quality is consistently achieved. That is why demanding customers the world over place their trust in Mozart quality.

The Fi-Tech Group proudly leads the way in assisting with the development of Fibre industry blades in partnership with Mozart technical expertise.

Who can do more?

Technical blades produced to individual specification on materials, hardness, edge and tolerances…

- Resilience

- Cutting performance

- Optimised lifetime

- Specialised geometries

- Grinding executions

- Quality control

- Optimised packaging solutions for trade or industry

- Material diversity

Just a few of the outstanding characteristics of Mozart industrial blades – proven time and time again.

Blades to the highest standards of hardness and surface finish when the going gets tough…

Blades coated in titanium, diamond, ceramic or chrome are excellently suited to meet the most taxing application demands. The excellent combination of a smooth cut, chemical resistance and hardness permits high cutting speeds coupled with impressive durability. Therefore, these blades can boast not only a brilliant cutting quality but often also the best value for money. Thanks to Mozart’s unsurpassed application know-how, we are able to give you competent and reliable advice in your choice of the coating best suited to your purposes.

Advantages of being a Mozart partner:

- Excellent price-performance ratio with consistent and high quality

- Highest standard of reliability due to strong logistics structure

- Individual customer support respectively contact persons

- Flexible and lean company structure

- Comprehensive product range

- Customized blades to suit your application

- Active support for customer development

- Assistance in complex cutting challenges

- Constant control in all manufacturing steps

- Microstructure analysis assures our high requirements on quality and durability of our blades

- Quality inspection between/at each manufacturing step for constant quality

Advantages of working with Fi-Tech:

Fi-Tech Europe stocks MKIV and MKV Lummus cutter blades as well Krupp and as 3 hole industrial blades at our warehouse in Sheffield. We also offer consignment stock programs for clients with large quantity annual usage. Contact our sales team to find out how Fi-Tech can help support your blade requirements.

To give you the best possible experience, this site uses cookies. Continuing to use www.fi-techeurope.com means you agree to our use of cookies. If you'd like to learn more about the cookies we use please visit our

To give you the best possible experience, this site uses cookies. Continuing to use www.fi-techeurope.com means you agree to our use of cookies. If you'd like to learn more about the cookies we use please visit our