filtertechnik.Europe

Since 1973 filtertechnik.Europe has continuously expanded in the field of filtration of liquid and high-viscosity media.

The result of years of experience of wire cloth and precise weaving techniques is a wide range of metallic filters especially suited to applications featuring high pressure and temperature. Wire cloth filter medium is particularly well suited in plastic processing environments. Production demands made on the quality of the product, as well as on safety and stability, are always rising. Therefore the demands on the purity of employed materials increase too.

Undesirable impurities such as metal, glass, sand or cracked materials are to be removed from the melt. Thus screen changers and filter media have to meet the highest demands; filtertechnik. Europe therefore operates the quality management system - ISO 9001:2000.

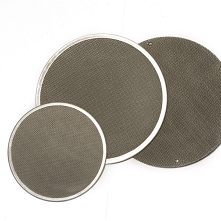

Wire cloth is the perfect filter media – giving defined and reproducible properties in production. Square mesh wire cloth has easily determinable geometric apertures with restricted tolerances – porosity is therefore constant over the entire area. The beneficial characteristics can be enhanced by arranging different wire cloth specifications in a combination of multiple layers i.e. a filter pack.

Advantages over other filter media:

- Chemical resistance

- High mechanical strength

- High wear resistance

- Good plastic deformation

- No decomposition of filter during filtration process

- Non-polluting

- Easily cleaned

- In-process cleaning by back flush

- Smooth surface

Areas of Application

Monomers

- PET and PA production

Polymers

- PET, PA6, PP, PE, PS

Staple fibres

- Fleece, Yarns

Recycling

- PE-foils, PVC-cables, PET-fibres, PET-foils

Non-woven filters

- Customer’s goal:

- Elongation of durability and increasing output

- fteu approach:

- Increase open screen face through use of pleatedfilter medium

- Modification of apron to avoid leakage

- Result:

- Short down-time periods

- Machines do not need to be modified

Foils

- Oriented films - packaging films, condenser films, adhesive tape films

- Flat films - deep-drawing films, tapes

- Foamed films - packaging films, isolation films, decoration films

- Blown films - carrier bag, rubbish bag, food films, hygienic films, shrinking films

Yarns

- Technical yarns

- Tyre cord, Belts, Rope, High-strength mono-filaments, Carpet yarns

- Textile yarns

- POY, FDY, DTY, HOY, Monofilaments

- High-elastic yarns

- Spanndex production

Masterbatch

- Filler material, Colorimeter, Stabilisers

Fleeces

- Hygienc articles, Supporting materials, Textiles

Tubes

- Pressure tubes, Medical tubes, Shrinking tubes

filtertechnik.Europe offers standardised (or - if requested - individual solutions) for almost any demand and most products are stocked for almost any established screens, filterbelts or filter elements.

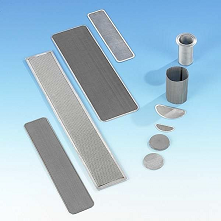

Extrusion filters

- One or multiple layers, various outlines and shapes

Spinneret filters

- Rimmed, pleated, one or multiple layers, also available with metal fibre felt

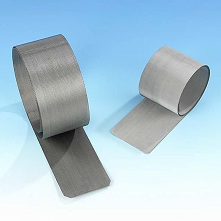

Filter belts

- High tensile strength, custom specifications, length as per your requirement

Filter candles

- For different applications in filtration of liquids, for high and low pressure, various shapes and geometrics, customized construction

Wire Cloth filters are available in the following materials:

- Steel

- Spring steel

- Stainless steel

- Heat resistant steel

- Copper

- Brass

- Tin-Bronze

- Nickle

- Monel (nickel alloy)

- Aluminium

To give you the best possible experience, this site uses cookies. Continuing to use www.fi-techeurope.com means you agree to our use of cookies. If you'd like to learn more about the cookies we use please visit our

To give you the best possible experience, this site uses cookies. Continuing to use www.fi-techeurope.com means you agree to our use of cookies. If you'd like to learn more about the cookies we use please visit our